Intelligent Planning

System

Demand and Supply planning optimization with scenario planning and what-if analysis

d-one plan enables you to align all business functions, to execute with speed on one single committed plan: transparency, reliability and agility.

D-ONE drives your company’s performance to the next level

Demand management

Production and Capacity Planning

Business Intelligence:

Cockpit & Analytics

Improve forecast predictions and optimize supply chain planning efficiency with our technology core made of advanced Machine Learning algorithms.

Optimize inventory levels, reduce costs and ensure on-time delivery. Identify potential bottlenecks and prioritize orders taking into account all relevant constraints..

Enable better visibility on operations and financial forecasting. Provides intelligent insights to facilitate decision-making and unlock new opportunities.

Demand management

Improve forecast predictions and optimize supply chain planning efficiency with our technology core made of advanced Machine Learning algorithms.

Production and Capacity Planning

Optimize inventory levels, reduce costs and ensure on-time delivery. Identify potential bottlenecks and prioritize orders taking into account all relevant constraints..

Business Intelligence:

Cockpit & Analytics

Enable better visibility on operations and financial forecasting. Provides intelligent insights to facilitate decision-making and unlock new opportunities.

All the planning processes can be operated with the desired

granularity: daily, weekly and monthly

D-one capabilities are add-ons

to your ERP

They are natively integrated and allow you to develop

the factory of the future.

Demand

Management

Production and

Capacity Planning

Business Intelligence:

Cockpit & Analytics

Demand management

Sales Forecasting with Machine Learning

Improving sales forecasting and reducing forecast error has become a strategic imperative for businesses irrespective of industry. Sales and demand Forecasting with machine learning provides the best possible system to improve forecast predictions and optimize supply chain planning automatically.

Better

Forecasting

Increased

Profitability

Lower

Inventory

Increased

Service Level

Demand management

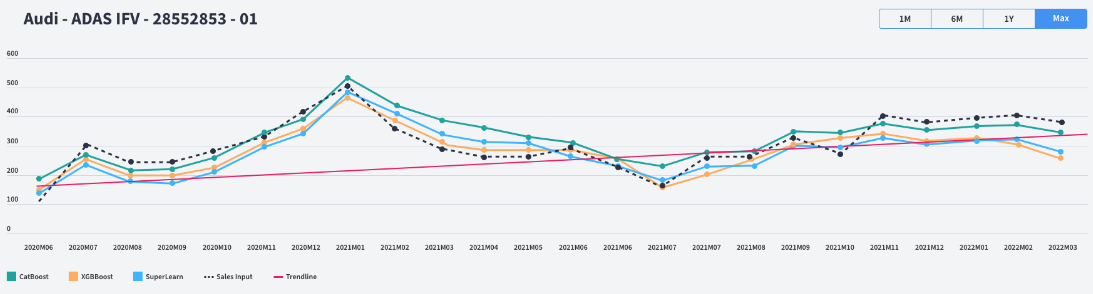

Machine Learning based forecast (use case)

It means large volumes of SKUs can be easily managed and processed with very high levels of accuracy through MAPE & Bias self-learning. The improved data means the most appropriate models can be selected and the most beneficial algorithms assigned.

Use case: we applied to B2B & B2C business. Used 2 years historical data to predict the future demand:

Accuracy

on B2C

MAPE

on B2C

Accuracy

on B2B

ML

Algorithms

Demand management

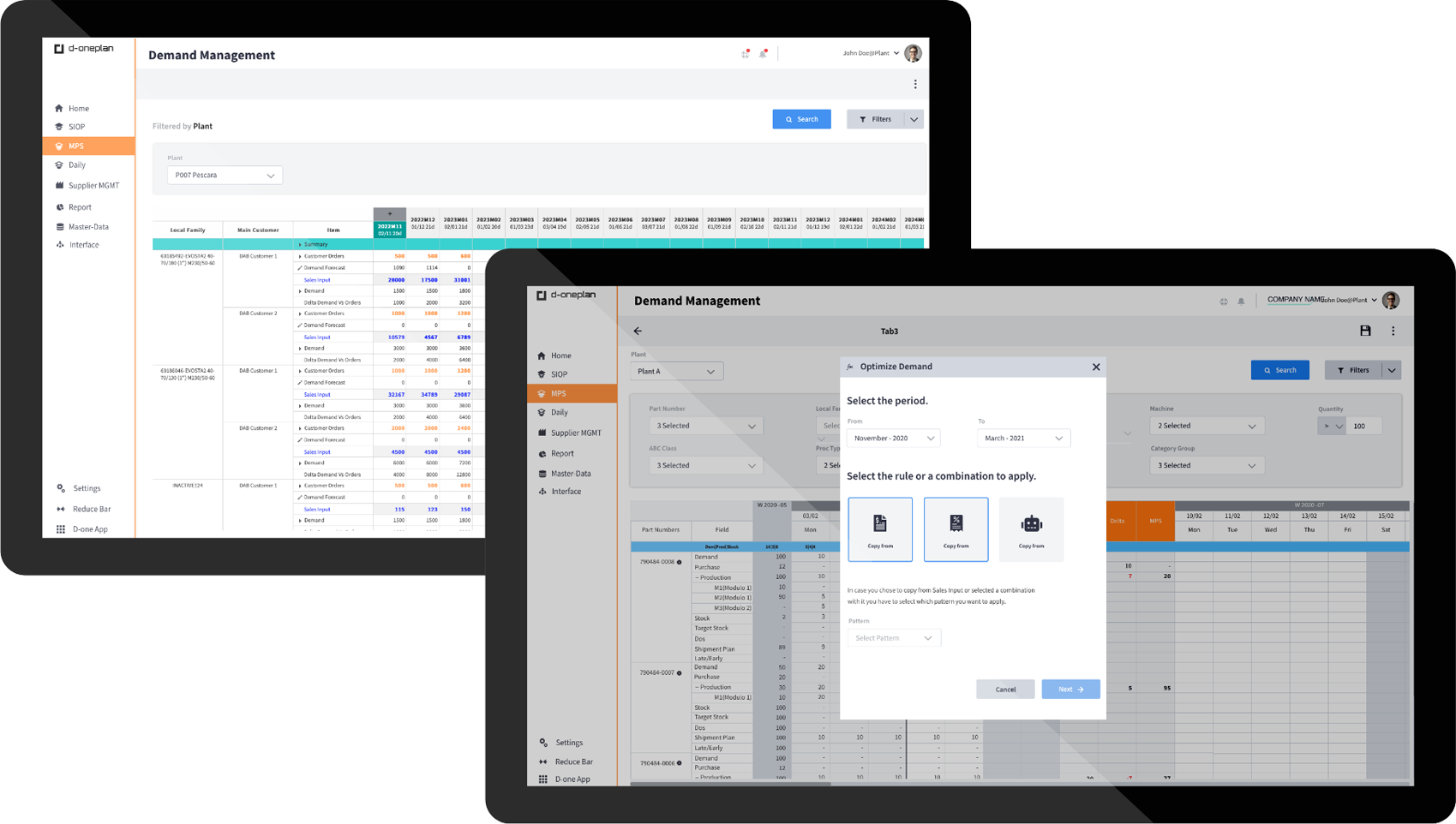

Demand Planning with Machine Learning (Demand Sensing)

Demand planning is the very foundation of the S&OP process. Collaborative demand planning takes reliable forecasting to the next level by also including key input from sales team.

Better

Forecasting

Increased

Profitability

Lower

Inventory

Increased

Service Level

Production and Capacity Planning

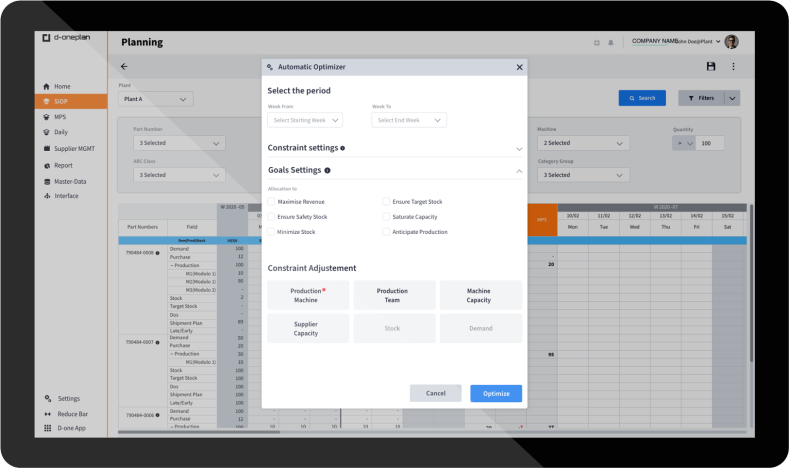

Supply planning and optimization (S&OP)

Detailed, robust and optimized supply plans based on the latest demand insights, potential bottleneck forecasts and targeted inventory levels. The machine capacity constrained production plans take sales, inventory and operations data into account and produce reliable, efficient and transparent results in the short and long term.

Business-wide

data integration

transparency

Removes

unnecessary

activities

Better capacity

utilization

Constraints &

machine

capacity

Production and Capacity Planning

Production planning and optimization (MPS)

Concurrently plan and monitor functionality, to quickly and easily manage supply to meet expected demand, while still respecting material and capacity constraints and hitting the inventory targets. Skillfully align supply to stated demand on a weekly or daily basis.

Business-wide

data integration

transparency

Removes

unnecessary

activities

Better capacity

utilization

Constraints &

machine

capacity

Production and Capacity Planning

Inventory and shipment planning

Bult-in optimizer with multiple goals functions to improve inventory and shipment planning. Cycle times will also be enhanced with the added benefit of automatic stock projection to help manage demand and production.

Inventory

Reduction

Improved

cicle times

Automatic Stock

projection

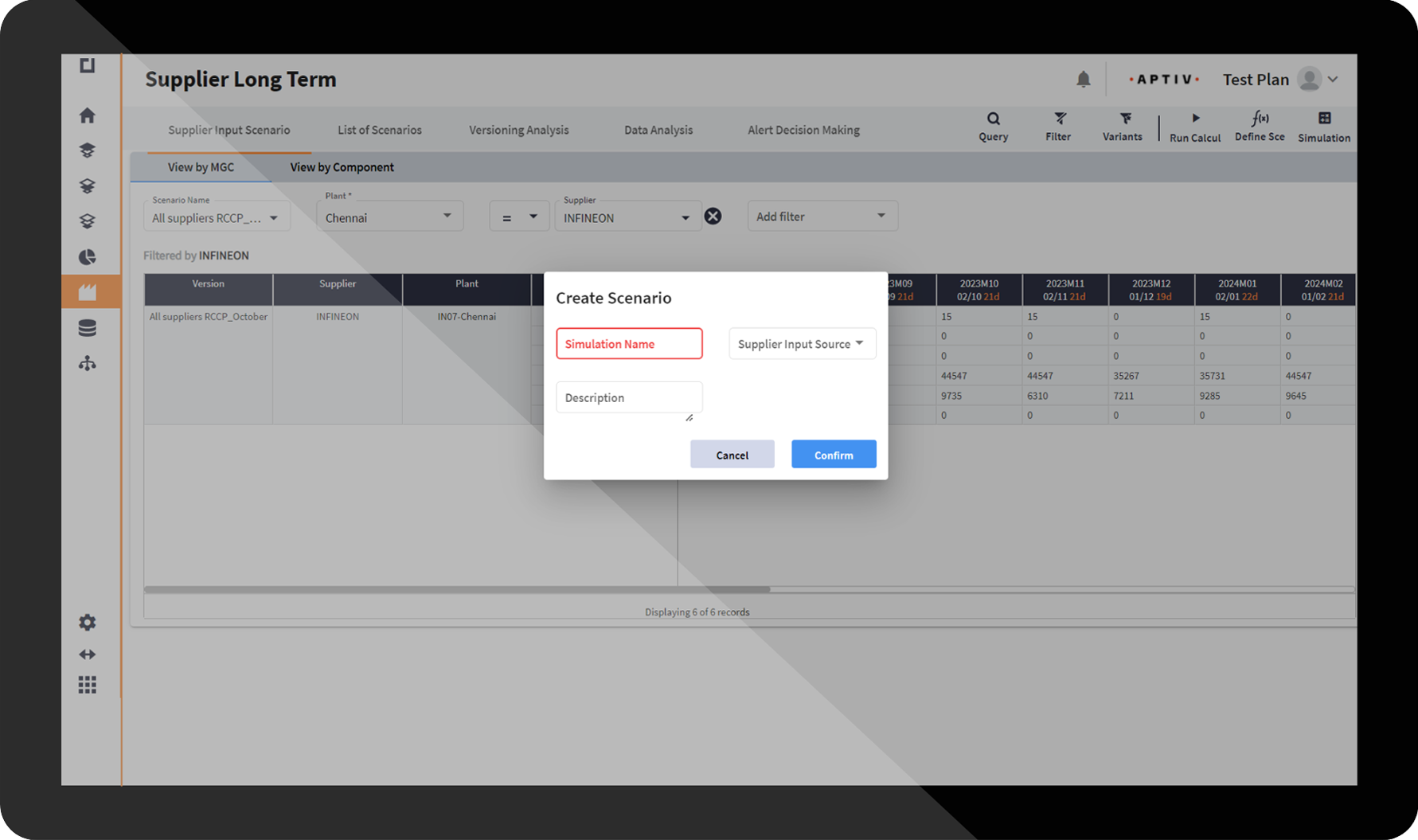

Production and Capacity Planning

Rough-Cut capacity planning

RCCP is a long-term plan capacity planning tool. It’s for balancing required and available capacity. It highlights, tracks and reports potentially critical situations with aging, checks key internal capacity and analyses supplier capacity so it can be better utilized and managed.

Meet the

capacity

requirement

Identify

potential critical

situations

Increase

delivery on time

performance

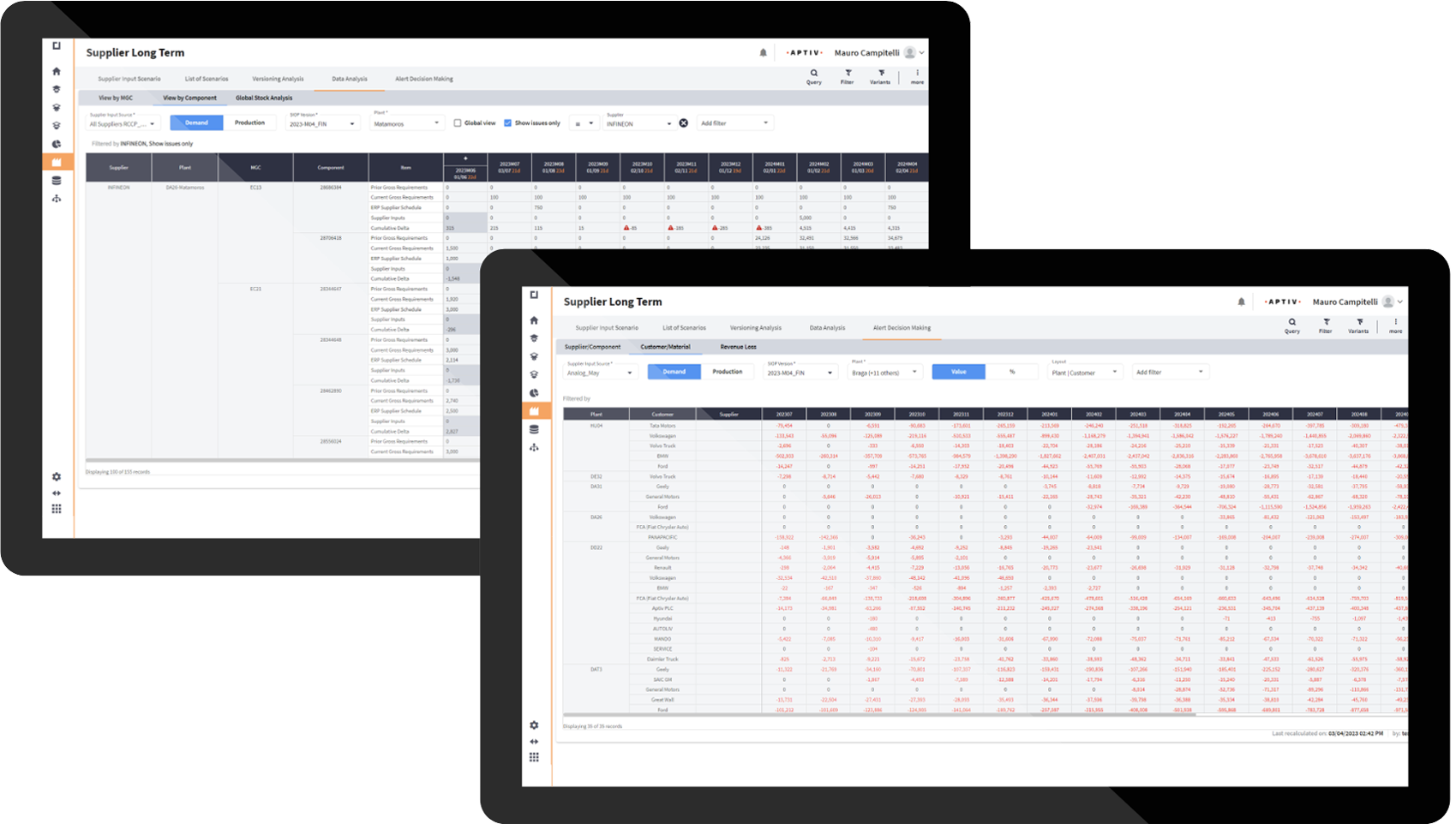

Production and Capacity Planning

Supplier management analysis

Easily identify and mitigate production issues caused by lack of components from suppliers by providing:

Identify

potential critical

situations.

Increase

delivery on time

performance

Understand

impact to

Customer

Meet the

capacity

requirement

Business Intelligence: Cockpit & Analytics

Forecast accuracy metric report

Accurate sales forecasting helps businesses figure out upcoming issues in their manufacturing and supply chains and course-correct before a problem arises. There are a number of formulas that planners can use to calculate forecast accuracy / forecast error, from the fairly simple to the quite complex. Two of the most common are MAPE and Bias.

Improve

capacity

utilization

Increase

reliability

Increase

accuracy

(MAPE, BIAS)

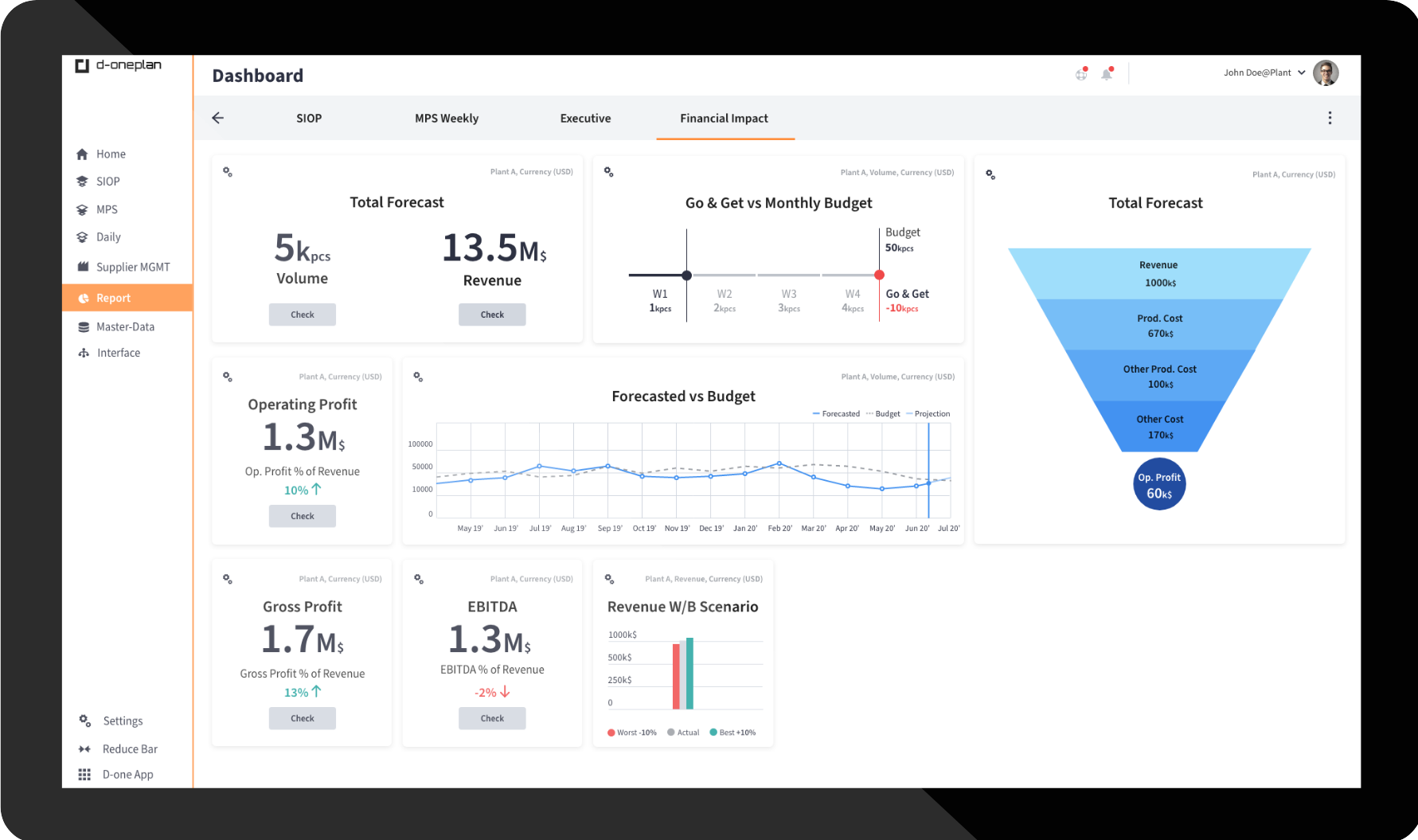

Business Intelligence: Cockpit & Analytics

Financial Impact, revenue and cost analysis

Linking the S&OP plan to the financial plan opens a whole new set of management opportunities and at the end of the day the Revenue Plan is important to management. Financial analysis plays a key role in producing inputs into Pre-S&OP and Executive S&OP.

Financials and

cashflow under

control

Sustainable

revenue growth

Monitor risks &

opportunities

Capitalise on

the economies

of scale

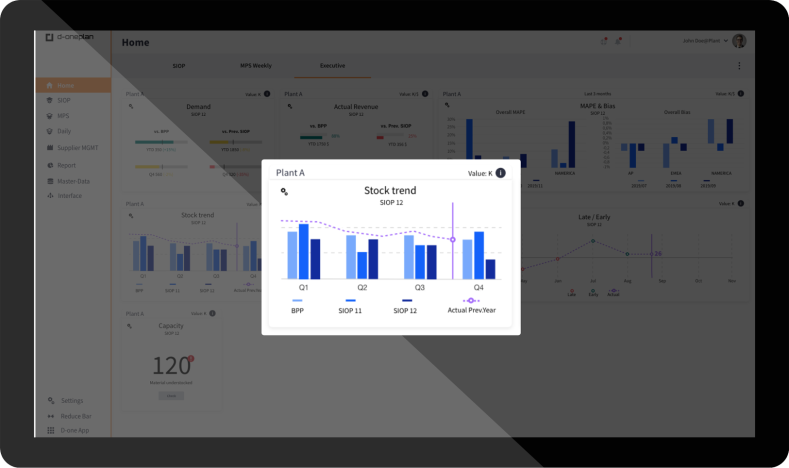

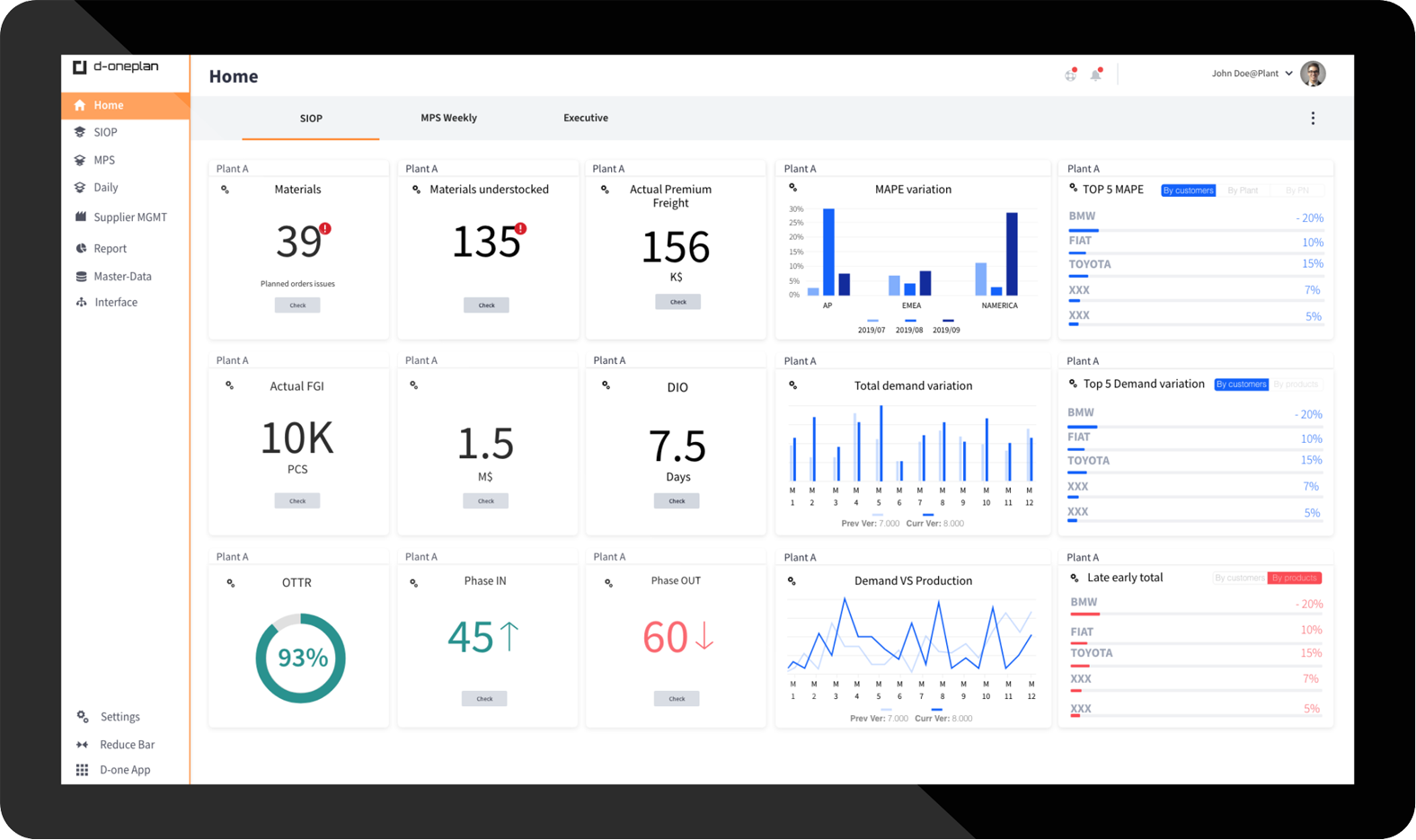

Business Intelligence: Cockpit & Analytics

Executive S&OP meeting summary dashboard

Key instrument to navigate the business towards its strategic objectives, facilitating better decision-making on a tactical planning horizon and balances service, cost and inventory for an improved Return On Capital Employed. Financial integration is a major step towards mature S&OP.

Align financial

and operational

plans

Understand

impact to

Customer

Simulate

multiple

scenarios

Business Intelligence: Cockpit & Analytics

What-if scenario simulation and versioning

Extraordinary easy way to create multiple versions (scenario simulation). When your production plan has been completed and checked, you can compare it against previous plans swiftly. At the end, you can finalize the plan and lunch it for the export to ERP.

Simulate

multiple

scenarios

Understand

impact to

Customer

Constraints &

capacity

management

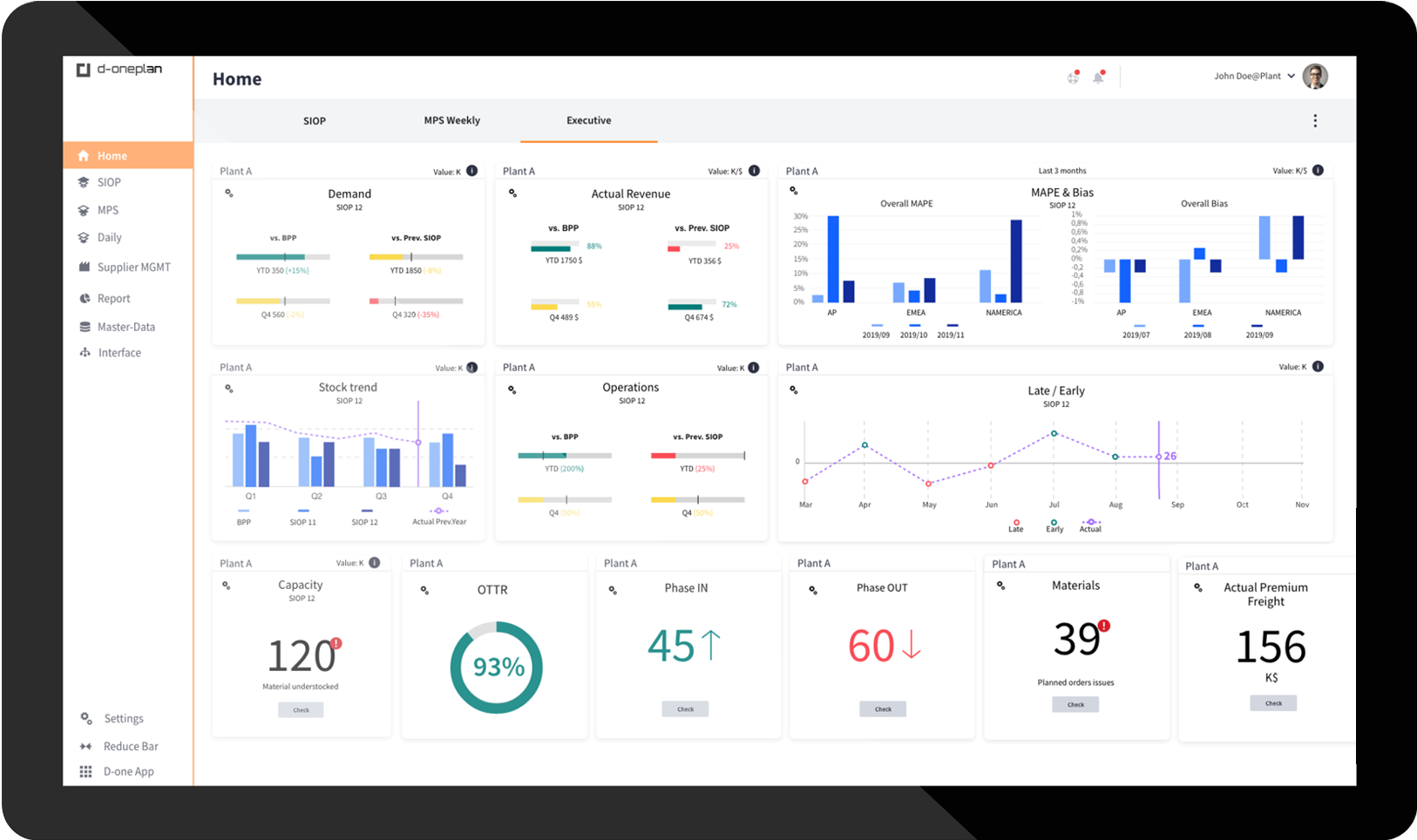

Business Intelligence: Cockpit & Analytics

BI KPI Dashboard and Data Visualization

Dashboard is a key instrument to focus on crucial KPI. It’s a combination of metrics & variations that’s used to convey performance as a single view, enabling informed decision-making.

Are you interested in a intelligent

planning system?